Laser technology was pioneered in the mid-twentieth century and has come a long way

since the first prototype. Today, lasers are one of the most popular tools in the manufacturing

industry. And for good reason lasers have allowed us to effortlessly perform complex

processes with ultrafine outcomes.

What is Laser Cutting Technology?

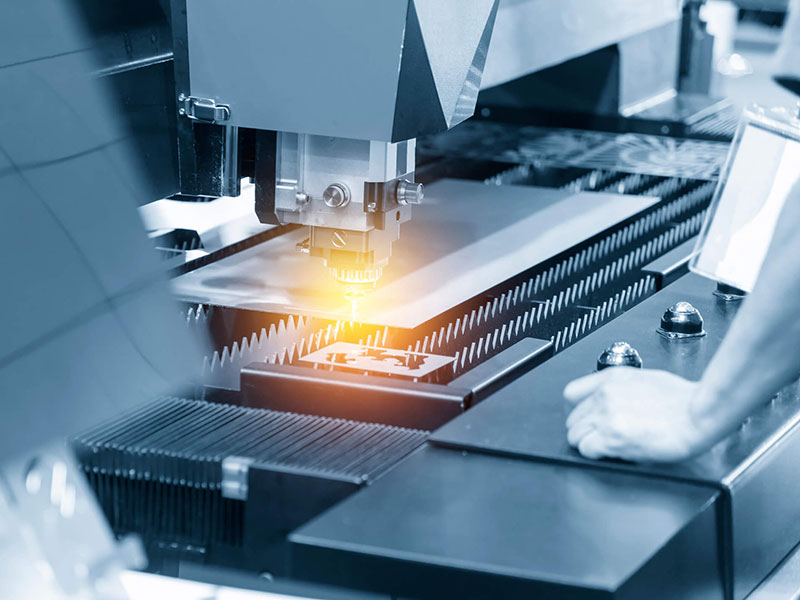

Laser cutting is a technology that uses a focused laser beam to cut materials, such

as metal, plastic, wood, or glass. The laser beam is generated by a high-power laser and is

precisely focused onto the material using a lens or a mirror. As the laser beam moves across

the material, it melts, burns, or vaporizes it, leaving a clean, precise cut edge.

The Advantages of Laser Technology

a). More Accurate

The advanced laser beams of today can be focused down to a thousandth of a millimetre.

This means that any measuring, marking, or cutting can be done with absolute precision.

With computer chips and medical device components getting increasingly minuscule, laser

technology offers superior accuracy and consistency that cannot be achieved with traditional

machining equipment.

Laser cuts are also incredibly clean, leaving no distortion or burrs on the remaining material.

This negates the need for an additional step to clean or finish the product after laser

processing.

b). Easy to Automate

With Industry 4.0 focusing on automation and the integration of technology with

manufacturing, laser technology can easily be added to production lines to achieve

unprecedented standardization.

Using lasers in manufacturing can lead to shorter cycle times, less maintenance, and more

cost-effective production. Previously labour-intensive and error-prone operations can be

done simply and flawlessly. When laser technology is combined with automation, processes

can be completed at astonishing speeds. Lasers are currently the quickest method of cutting

and welding on the production line.

c). Flexible Uses

Lasers can work on a diverse range of materials including fabric, plastic, glass, and metal.

Because laser parameters can be adjusted at any time, a single laser can perform numerous

manufacturing tasks such as cleaning, etching, cutting, or welding.

Unlike other comparable technologies, most laser machines are contactless, allowing them

to be used on objects of various geometrical complexities while maintaining the integrity of

their surfaces.

Investing in laser equipment has a high return on investment as it reduces redundancies

and streamlines operations. The applications of lasers are increasing each day, providing

more potential for the manufacturing floor.

d). Better for the Environment

Lasers use a fraction of the energy of their conventional counterparts. More efficient energy

consumption is essential for companies that want to lower production costs and reduce their

emissions and carbon output.

Lasers can also replace manufacturing methods that require consumables like welding

fluxes, steel grits, or ink and labels. This prevents a considerable amount of waste and

avoids the emissions associated with having to produce and transport these consumables

as well.

Finally, laser equipment can be remarkably compact, allowing manufacturers to build more

economical production lines and work within a smaller, more optimized factory footprint.

Top Applications of Lasers

a). Laser Cutting

Laser cutting uses a focused high-power laser beam to rapidly irradiate material and

produce very fine cuts or patterns. Lasers can effortlessly slice through dense materials

such as titanium or steel with smooth incisions and no mechanical or heat stress in the

surrounding areas.

Laser cutting technology is superior to conventional cutting machines because its operations

can be performed at ultrafast speeds, with micron-level precision and repeatable

consistency. Since the material stays stationary during the whole process it does not sustain

any surface wear.

b). Laser Engraving

Laser engraving uses the same laser beam to make a material’s surface vaporize instantly

as it marks out a barcode, character, or pattern. Laser engraving is now one of the most

popular marking methods due to its fast production speed and quick repetition cycles

UV laser engraving is extremely powerful and is commonly used to imprint permanent

unique identification numbers on components and products to ensure manufacture

traceability. UV laser engraving is highly durable and can be applied on surfaces that are

flat or curved.

c). Laser Welding

Laser welding is very effective for complex materials that cannot be handled by conventional

methods. It works by using laser radiation to melt material down to a molten and joinable

state. No electrodes are needed and therefore no contamination or deformation to the

material occurs.

A large range of materials can be welded together by laser, including two different kinds of

metals or a metal and a plastic. Although laser welding is precise enough to form welds

smaller than a millimetre, these welds are much stronger than they would be if using

traditional soldering or glue.

d). Laser Texturing

Laser texturing uses controlled laser ablation to remove specific materials from the surface

of an object. This process is generally used to create additional roughness and textural

micro-patterns such as dimples and freeform grooves on a material’s surface.

Creating surface textures can improve the performance of certain components. For

example, rough textures on medical implants can provide additional surface area for new

tissue to anchor. Likewise, laser textured mechanical seals have improved lubricant

retention and durability.

Conclusion:

Laser technology is quickly replacing many tedious mechanical processes. Automated laser

machines create safer manufacturing floors by eliminating risky manual processes. Through

investing in laser technology, manufacturers can improve productivity, lower operation

costs, reduce maintenance, and produce exceptionally accurate and repeatable results.